Conveyor Batch Sequence

Technical Goal

Implement a function that takes an array of integers and returns a new array with the elements sorted in ascending order. The original array must remain unchanged.

Constraints

nums: An array of integers (can include negative numbers and duplicates).- Return a new sorted array; do not modify the original.

- Empty input should return an empty array.

Example 1:

Input: nums = [12, 7, 7, 9] Output: [7, 7, 9, 12] Explanation: Duplicate weights remain while the list climbs from lightest to heaviest.

Example 2:

Input: nums = [] Output: [] Explanation: An empty feed results in an empty ordered list.

Example 3:

Input: nums = [-2, 5, -2, 3] Output: [-2, -2, 3, 5] Explanation: Negative markers and positive weights are preserved in ascending order.

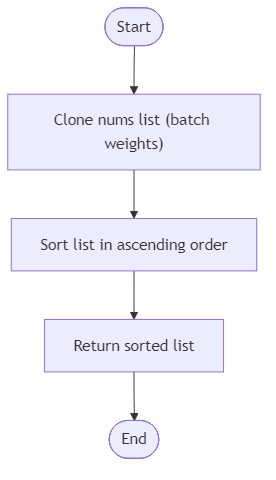

Algorithm Flow

Recommendation Algorithm Flow for Conveyor Batch Sequence - Budibadu

Best Answers

java

import java.util.*;

class Solution {

public int[] conveyor_batch_sequence(int[] nums) {

int[] result = nums.clone();

Arrays.sort(result);

return result;

}

}Comments (0)

Join the Discussion

Share your thoughts, ask questions, or help others with this problem.